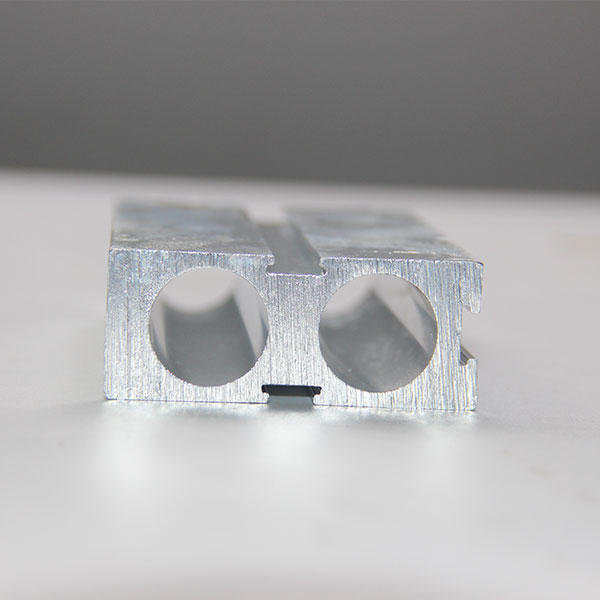

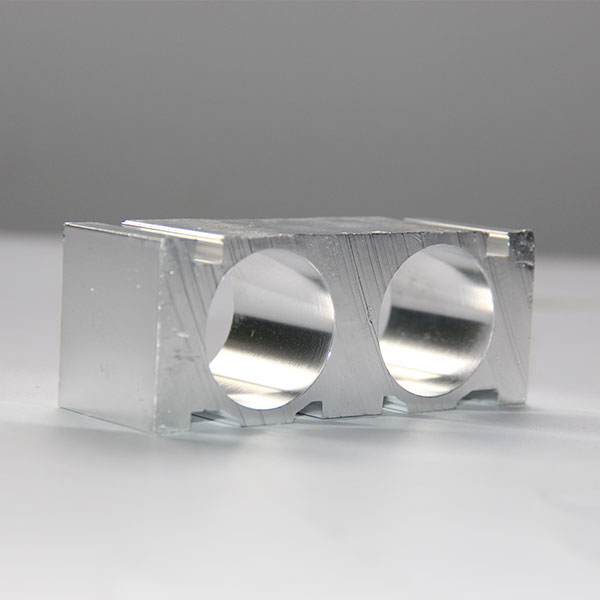

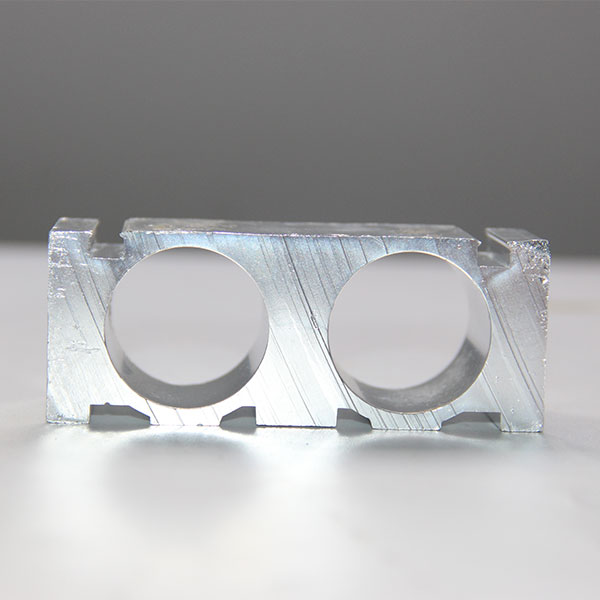

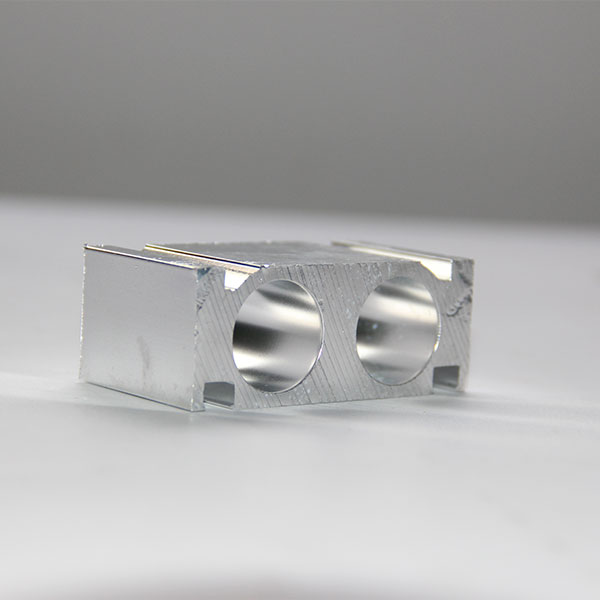

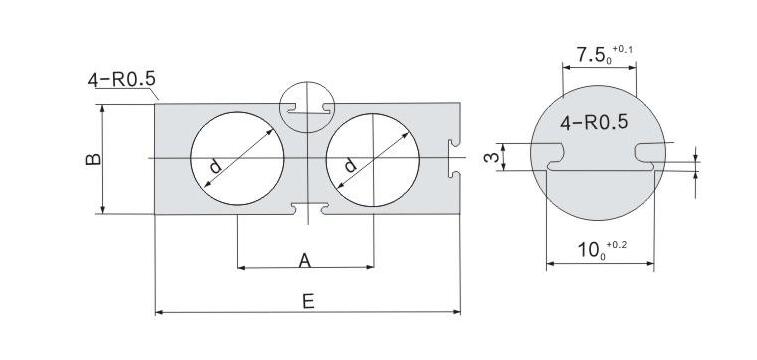

TN/TR/TCM/CXS DUAL ROD AIR CYLINDER ALUMINIUM TUBE

ʻO TN (φ10-50) Pūʻali Paipu Pahu Poʻo ʻElua

| No | d | E | A | B |

| 1 | φ10 | 42 | 18 | 17 |

| 2 | φ16 | 54 | 24 | 21 |

| 3 | φ20 | 62 | 28 | 25 |

| 4 | φ25 | 73 | 34 | 30 |

| 5 | φ32 | 96 | 42 | 40 |

| 6 | φ40 | 112 | 56 | 48 |

| 7 | φ50 | 135.5 | 60.5 | 58 |

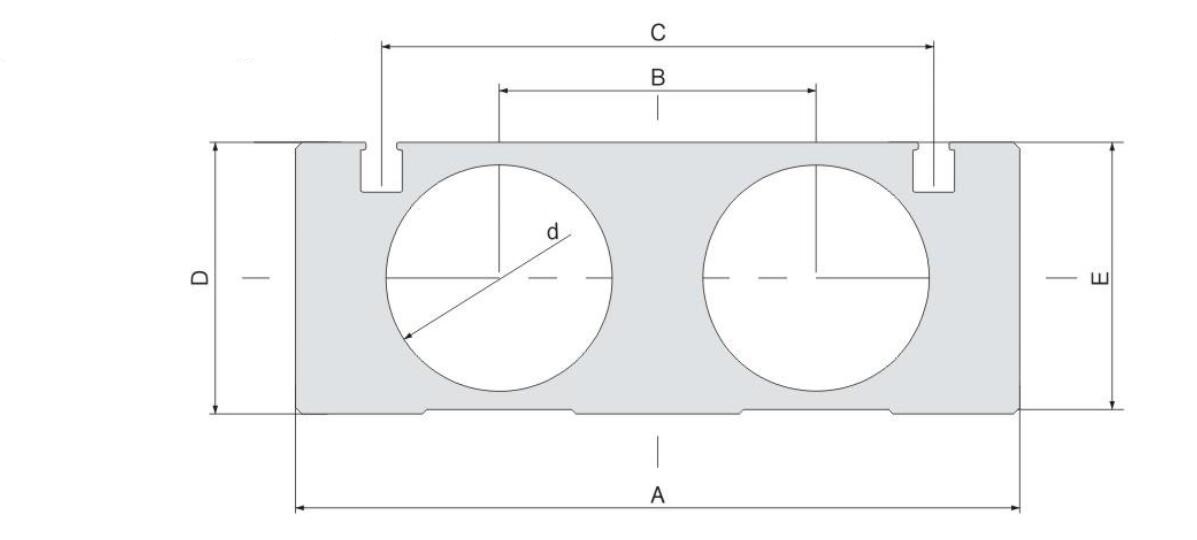

ʻO TR (φ6-32) Pūnaehana Paʻa Paʻa Paʻa Paʻa Paʻa

| NO | d | E | A | T | B | b | D |

| 1 | Φ10 | 46.4 | 20 | 33.8 | 17.3 | 7.3 | 25.8 |

| 2 | Φ16 | 58.5 | 25 | 41.2 | 20.3 | 10 | 33.4 |

| 3 | Φ20 | 64.4 | 28 | 53 | 25.3 | 12.8 | 37.5 |

| 4 | Φ25 | 80.4 | 35 | 64 | 30.3 | 15.3 | 45.5 |

| 5 | Φ32 | - | - | P IS pili ia belou darwing | |||

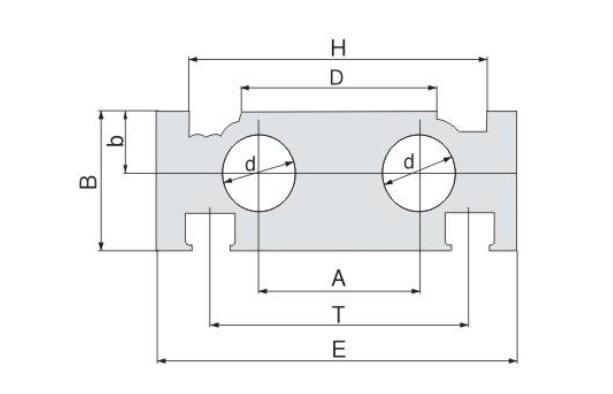

ʻO CXS (φ10-32) Pūʻani Cylinder Tube

| No | d | E | A | T | B | b | D | H |

| 1 | φ10 | 46 | 20 | 33.8 | 17 | 7.1 | 25.8 | 38 |

| 2 | φ15 | 58 | 25 | 41.2 | 20 | 10 | 33.4 | - |

| 3 | φ20 | 64 | 28 | 53 | 25 | 12.5 | 37.5 | 52.5 |

| 4 | φ25 | 80 | 35 | 64 | 30 | 15 | 45.5 | 67 |

| 5 | φ32 | 98 | 48 | 76 | 38 | 19 | 57.5 | 81.2 |

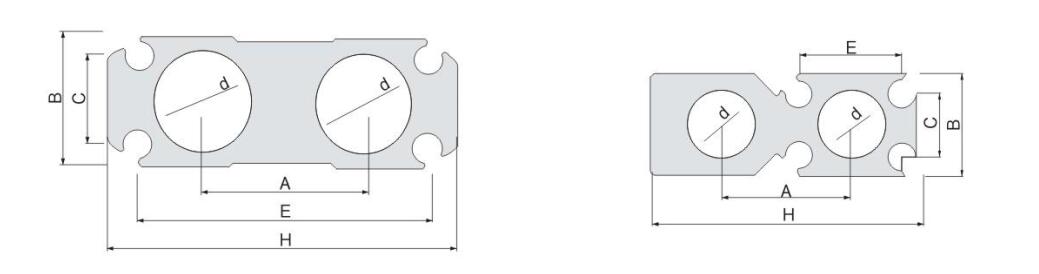

ʻO CXS-J (φ6-32) Pūʻulu Paipu Paʻa Paʻa ʻElua

| NO | d | H | B | A | E | C |

| 1 | φ6 | 32 | 13.4 | 16 | 10.6 | 8 |

| 2 | φ10 | 42 | 15 | 20 | 16 | g |

| 3 | φ15 | 54 | 19 | 25 | 45 | 13 |

| 4 | φ20 | 62 | 24 | 29 | 51 | 18 |

| 5 | φ25 | 73 | 29 | 35 | 59 | 23 |

| 6 | φ32 | 94 | 37 | 45 | 73 | 31 |

Mea o ka Aluminum Alloy Profile Aluminum pneumatic cylinder tube: alumini alumini 6063 T5

ʻO kā mākou lōʻihi maʻamau ʻo 2000mm, inā pono ka lōʻihi ʻē aʻe, e ʻoluʻolu e haʻi mai iā mākou.

Anodized ili: Inner tube-15±5μm Outer tube-10±5μm

E like me ka hoʻolālā FESTO, SMC, Airtac, Chelic etc.

E like me ka ISO 6430 ISO6431 VDMA 24562 ISO15552 etc.

Hoʻohana ʻia no ka cylinder maʻamau, ka cylinder compact, mini cylinder, Dual Rod cylinder, Slide cylinder, Slide Table cylinder, Gripper etc. No kekahi mau pahu kūikawā.

Huina Kemika:

| Hoʻohui Kimia | Mg | Si | Fe | Cu | Mn | Cr | Zn | Ti |

| 0.81 | 0.41 | 0.23 | <0.08 | <0.08 | <0.04 | <0.02 | <0.05 |

Hōʻike:

| ʻImi ʻino (N/mm2) | Ka ikaika hua (N/mm2) | Ka maʻalahi (%) | ʻOoleʻa ʻili | Ka pololei anawaena | ʻOloʻeloʻe Kuloko | Pololei | Hapa Mānoanoa |

| Sb 157 | S 0.2 108 | S8 | HV 300 | H9-H11 | < 0.6 | 1/1000 | ± 1% |

ʻO ka hoʻomanawanui o ka pahu alumini alumini:

| TORLERANCE O ALUMINIUM ALLOY TUBE | ||||||

| Ka nui o ka Bore | TORLERANCE | |||||

| mm | H9(mm) | H10(mm) | H11(mm) | |||

| 16 | 0.043 | 0.07 | 0.11 | |||

| 20 | 0.052 | 0.084 | 0.13 | |||

| 25 | 0.052 | 0.084 | 0.13 | |||

| 32 | 0.062 | 0.1 | 0.16 | |||

| 40 | 0.062 | 0.1 | 0.16 | |||

| 50 | 0.062 | 0.1 | 0.16 | |||

| 63 | 0.074 | 0.12 | 0.19 | |||

| 70 | 0.074 | 0.12 | 0.19 | |||

| 80 | 0.074 | 0.12 | 0.19 | |||

| 100 | 0.087 | 0.14 | 0.22 | |||

| 125 | 0.1 | 0.16 | 0.25 | |||

| 160 | 0.1 | 0.16 | 0.25 | |||

| 200 | 0.115 | 0.185 | 0.29 | |||

| 250 | 0.115 | 0.185 | 0.29 | |||

| 320 | 0.14 | 0.23 | 0.36 | |||

FAQ:

Q1: He aha ka lua pneumatic cylinder?

A: ʻO ka pahu pālua pneumatic cylinder ka hana o ʻelua piston rods i ka pneumatic cylinder e hana ana i ka neʻe ʻana o ka linear reciprocating motion i loko o ka pneumatic cylinder e hoʻohua ai i ka ea, a ʻo ke kaomi ea e hoʻomake i ka piston e hoʻoulu a hoʻonui i ka ikehu mechanical.Nā wahi noi o ka pneumatic cylinder s: paʻi, semiconductors, mana automation, robots, etc.

Q2: No ke aha e hoʻohana ai i ke koʻokoʻo piston pālua no ka pneumatic cylinder?

A: ʻO ka hana ʻelua-piston rod e hana i ka pneumatic cylinder i ka anti-bending a me ka anti-torsion performance, a hiki ke kū i nā ukana nui a me nā ukana lateral.

Aia nā mea pad anti-collision ma nā ʻaoʻao ʻelua, hiki ke hoʻolōʻihi i ka wikiwiki o ka hopena a hoʻolōʻihi i ke ola lawelawe.

Q3: ʻO wai nā hiʻohiʻona pneumatic cylinder me ʻelua piston rod?

A: Ua loaʻa iā Dual rod pneumatic cylinder SMC standard CXSM, Airtac standard TN, Airtac standard STM etc.

Q4: Ua like paha me ka maʻamau me SMC a i ʻole Airtac?

A: ʻOiaʻiʻo, ua ʻae mākou i kā lākou kūlana no ka hana ʻana.

Q5: He aha ka mea e hoʻolohe ai i ka hoʻohana ʻana i ka cylinder pneumatic?

A: Ma lalo o ka wela kiʻekiʻe a i ʻole nā kūlana corrosive, pono e hoʻohana ʻia nā kiʻekiʻe wela a i ʻole corrosive pneumatic cylinder s.