Pākē ʻOihana Kina S45c SAE1045 C45 Wela ʻO ka Pepa kila kabone i ʻōwili ʻia

Lawe i ke kuleana piha e hoʻokō i nā koi āpau o kā mākou mea kūʻai;e hoʻokō mau i ka holomua ma ka paipai ʻana i ka ulu ʻana o kā mākou mea kūʻai;e lilo i hoa hana paʻa hope loa o nā mea kūʻai aku a hoʻonui i ka makemake o nā mea kūʻai aku no ka Chinese Professional China S45c SAE1045 C45 Hot Rolled Carbon Steel Sheet, Ke manaʻoʻiʻo nei mākou i ka maikaʻi ma mua o ka nui.Ma mua o ka hoʻokuʻu ʻia ʻana o ka lauoho, aia ka mākaʻikaʻi koʻikoʻi kiʻekiʻe i ka wā o ka mālama ʻana e like me nā kūlana maikaʻi o ka honua.

Lawe i ke kuleana piha e hoʻokō i nā koi āpau o kā mākou mea kūʻai;e hoʻokō mau i ka holomua ma ka paipai ʻana i ka ulu ʻana o kā mākou mea kūʻai;lilo i hoa hui mau hope loa o nā mea kūʻai aku a hoʻonui i ka makemake o nā mea kūʻai aku noPepa kila Kina, Pepa kila i olokaa wela, Uaʻike pono kā mākou hui i nā koi o ka mākeke ma nā'āina likeʻole, a hiki iā ia ke hoʻolako i nā huahana kūpono kūpono a me nā hoʻonā i nā kumukūʻai maikaʻi loa i nā mākeke likeʻole.Ua hoʻonohonoho mua kā mākou hui i kahi hui ʻike, noʻonoʻo a kuleana e hoʻomohala i nā mea kūʻai aku me ka manaʻo multi-win.

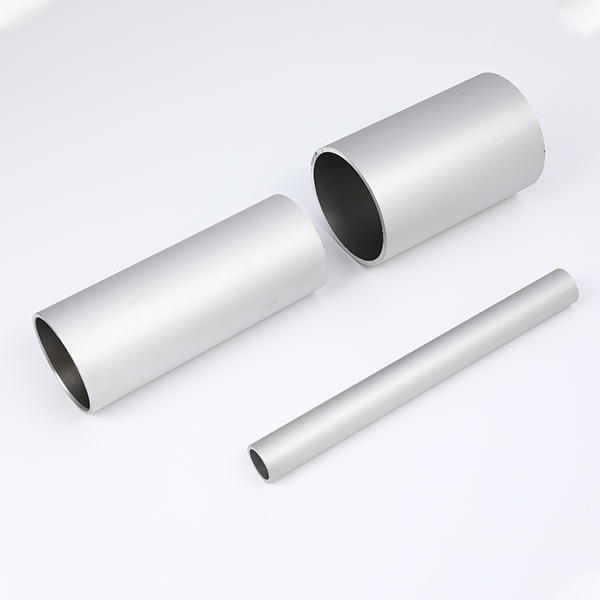

ʻO ka pneumatic cylinder hydraulic piston rod i kapa ʻia he koʻokoʻo chrome-plated.He koʻokoʻo ia me ka ʻili i mālama ʻia e ka wili kūikawā a me ka paʻa chrome paʻakikī.Hoʻohana nui ʻia ia i loko o nā cylinders like ʻole, hydraulic cylinders, packaging, woodworking, spinning, printing and dyeing machines, die-casting parts a me nā mea hoʻoili ʻokoʻa ʻē aʻe ma muli o kona paʻakikī, hiki ke hoʻonui i ke ola lawelawe o nā mīkini kikoʻī maʻamau a me nā lako.

Hoʻohana mākou i ka kikoʻī kikoʻī i huki ʻia, honing a polishing e hana i ka pneumatic cylinder hydraulic piston rod, kēlā me kēia pahuhopu ʻenehana e hoʻokō i ke kūlana aupuni.

Hōʻike kikoʻī

Mea Hana:CK45(GB/T699-1999)

Mea kikoʻī mīkini:

Ka ikaika tensile(Mpa):≥600N/mm2

0,2 Hoʻoulu ʻia (Mpa): ≥355N/mm2

Elongation: min.16%

ʻO ka mānoanoa o Chrome Plated:φ<20mm≥15μm,maiφ20mm>20μm

ʻO ʻākala: Ra<0.2

Paʻa Chrome Paʻakikī: 850HV-1050HV

Ka hoʻomanawanui anawaena: f7,f8

Pololei: <0.1um/1000mm

Ovality: <1/2 anawaena hoʻomanawanui

Loiloi Corroseston Test: ISO 10289:1999,IDT

Anawaena waho:3-120mm (GCr15) 3-40m(SUS440C)

Ke kūlana o ka hāʻawi ʻana: maʻamau, Induction Harden, Q + T

Papa haku mele

| KĀMĀKĀWAI (%) | |||||||

| Mea waiwai | C% | Mn% | Si% | S% | P% | V% | Cr% |

| <= | |||||||

| CK45 | 0.42-0.50 | 0.50-0.80 | 0.17-0.37 | 0.035 | 0.035 | ||

| ST52 | <=0.22 | <=1.6 | <=0.55 | 0.035 | 0.035 | 0.10-0.20 | |

| 20MnV6 | 0.16-0.22 | 1.30-1.70 | 0.1-0.50 | 0.035 | 0.035 | ||

| 42CrMo4 | 0.38-0.45 | 0.60-0.90 | 0.15-0.40 | 0.03 | 0.03 | 0.90-1.20 | |

| 4140 | 0.38-0.43 | 0.75-1.0 | 0.15-0.35 | 0.04 | 0.04 | 0.80-1.10 | |

| 40Cr | 0.37-0.45 | 0.50-0.80 | 0.17-0.37 | 0.80-1.10 | |||

| Anawaena | Kaumaha | Hoʻomanawanui | Hoʻomanawanui | Hoʻomanawanui |

| mm | Kg/m | f7(μm) | f8(μm) | h6(μm) |

| 6 | 0.22 | -10–22 | -10–28 | 0–9 |

| 8 | 0.39 | -13–28 | -13–35 | 0–9 |

| 10 | 0.62 | -13–28 | -13–35 | 0–11 |

| 12 | 0.89 | -16–34 | -16–43 | 0–11 |

| 16 | 1.58 | -16–34 | -16–43 | 0–11 |

| 18 | 2.00 | -16–34 | -16–43 | 0–13 |

| 20 | 2.47 | -20–41 | -20–53 | 0–13 |

| 22 | 2.99 | -20–41 | -20–53 | 0–13 |

| 25 | 3.86 | -20–41 | -20–53 | 0–13 |

| 28 | 4.84 | -20–41 | -20–53 | 0–13 |

| 30 | 5.55 | -20–41 | -20–53 | 0–16 |

| 32 | 6.32 | -25–50 | -25–64 | 0–16 |

| 36 | 8.00 | -25–50 | -25–64 | 0–16 |

| 38 | 8.91 | -25–50 | -25–64 | 0–16 |

| 40 | 9.87 | -25–50 | -25–64 | 0–16 |

| 45 | 12.49 | -25–50 | -25–64 | 0–16 |

| 50 | 14.22 | -25–50 | -25–64 | 0–19 |

| 55 | 15.43 | -30–60 | -30–76 | 0–19 |

| 60 | 18.66 | -30–60 | -30–76 | 0–19 |

| 65 | 26.07 | -30–60 | -30–76 | 0–19 |

| 70 | 30.23 | -30–60 | -30–76 | 0–19 |

| 75 | 34.71 | -30–60 | -30–76 | 0–19 |

| 80 | 39.49 | -30–60 | -30–76 | 0–22 |

| 85 | 44.58 | -36–71 | -36–90 | 0–22 |

| 90 | 49.98 | -36–71 | -36–90 | 0–22 |

| 95 | 55.68 | -36–71 | -36–90 | 0–22 |

| 100 | 61.70 | -36–71 | -36–90 | 0–22 |

He aha nā kūlana hoʻomanawanui f7 a me f8:

ʻOi aku ka nui o ka hoʻomanawanui ʻana o f8 ma mua o ka f7, a ke kau nei ka hoʻonohonoho ʻana ma muli o ke kiʻekiʻe o ka pae hoʻomanawanui lua.No ka laʻana, inā ʻo 10-18 ka nui kumu, f8(-0.016,-0.034), f7(-0.016,-0.027), ua like ka deviation o nā ʻae ʻelua, ʻoi aku ka liʻiliʻi o ka f7, a me ka wehe ʻana. ʻoi aku ka liʻiliʻi o ka laulā o ka hoʻonohonoho kūpono.

Kahe Hana

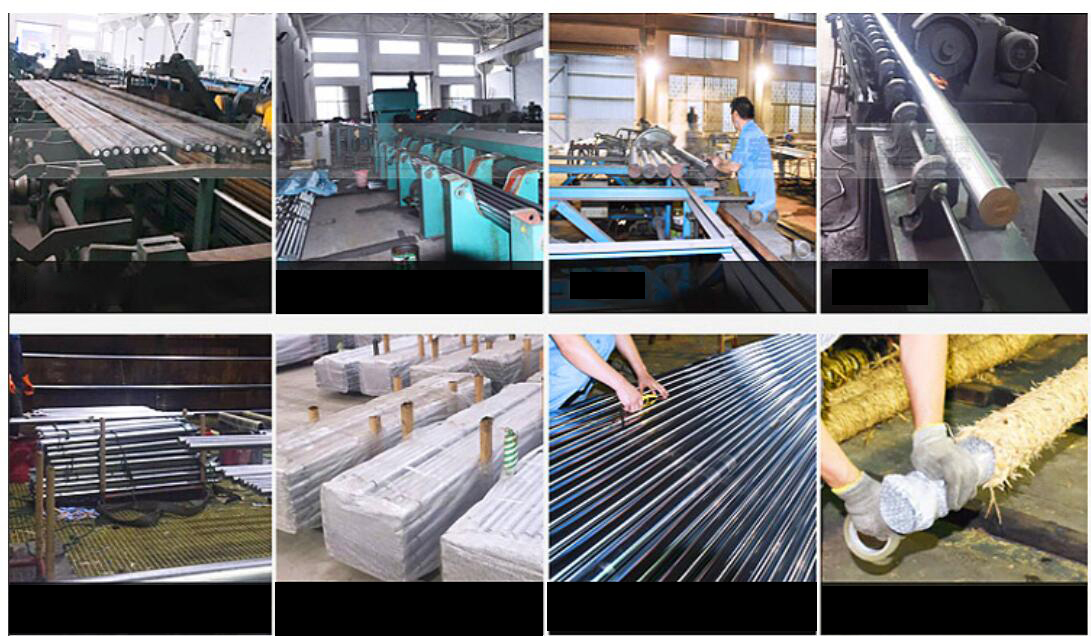

1 KaʻAnuʻu: Peeling/Hui anu:

ʻO ke kiʻi anuanu he ʻenehana hana o ka pneumatic cylinder piston rod.No ka pneumatic cylinder hard chrome plated rod, anu ke kiʻi ʻana i ke kaha kiʻi ma lalo o ke kūlana o ka mahana maʻamau i mea e loaʻa ai kekahi ʻano a me kekahi mau waiwai mechanical.Ke hoʻohālikelike ʻia me ka hana wela, ʻoi aku ka maikaʻi o nā huahana huki anu i ka pololei o ka nui a me ka hoʻopau ʻana i ka ʻili.

2 KaʻAnuʻu: Hoʻopololei

ʻO kēia kaʻina hiki iā mākou ke hōʻoia i ka pololei o ke koʻokoʻo paʻa chrome paʻa.He mea koʻikoʻi loa ia, i ka wā e hoʻokomo ai i loko o ka cylinder pneumatic.ʻO 0.2mm/m ka pololei pololei.

3 ʻanuʻu: Honing

ʻO ka hoʻoili ʻana ʻo Honing kahi ʻano hana hana maikaʻi e hiki ai i ka pneumatic cylinder piston rod surface e hoʻokō i ke kiʻekiʻe kiʻekiʻe, kiʻekiʻe o ka ʻili a me ke ola lōʻihi.Hiki iā ia ke hoʻomaikaʻi maikaʻi i ka pololei dimensional, hoʻohālikelike i ka pololei a hōʻemi i ka waiwai Ra, akā ʻaʻole hiki ke hoʻomaikaʻi i ke kūlana o ka lua a me nā mea ʻē aʻe.

4 KaʻAnuʻu: Steel Rod Polishing

ʻO ka polishing e pili ana i ka hoʻohana ʻana i nā hopena mechanical, chemical a electrochemical paha e hōʻemi i ka ʻili o ka ʻili o ka pneumatic cylinder piston rod e loaʻa ai kahi ʻālohilohi a maʻalahi.ʻO ia ka hoʻohana ʻana i nā mea hana polishing a me nā ʻāpana abrasive a i ʻole nā mea hoʻoliʻiliʻi ʻē aʻe e hoʻololi i ka ʻili o ka pneumatic cylinder piston rod.

5 KaʻAnuʻu: Chrome Plating

Hoʻopili ʻo Chrome plating i ka hana o ka hoʻopaʻa ʻana i ka chromium ma ke ʻano he uhi ʻana ma luna o ke koʻokoʻo paʻa chrome paʻakikī pneumatic.

He kiʻekiʻe loa ka paʻakikī o ka papa chromium-plated, a hiki ke hoʻololi i kona paʻakikī i loko o kahi ākea o 400-1200HV e like me ke ʻano o ka hopena plating a me nā kūlana kaʻina.ʻO ka papa chrome-plated he pale wela maikaʻi.Ke hoʻomehana ʻia ma lalo o 500 ℃, ʻaʻohe hoʻololi ʻike i ka ʻōlinolino a me ka paʻakikī.E hoʻomaka ana ka mahana e oxidize a hoʻololi i ka waihoʻoluʻu ke piʻi ka mahana ma luna o 500 ℃, a e emi ka paʻakikī i ka wā ma luna o 700 ℃.He liʻiliʻi ka pānaʻi kuʻekuʻe o ka papa chrome, ʻoi aku ka nui o ka pākuʻi maloʻo, ʻo ia ka haʻahaʻa loa ma waena o nā metala āpau.No laila, ʻoi aku ka maikaʻi o ka pale chrome-plated.

He paʻa kemika maikaʻi ka papa chromium plating.ʻAʻohe hopena i ka alkali, sulfide, nitric acid a me ka hapa nui o nā waikawa organik, akā hiki ke hoʻoheheʻe ʻia i loko o ka waika pneumatic (e like me ka waika pneumatic) a me ka waikawa sulfuric wela.Ma ka laulā kukui ʻike, ʻo ka reflectivity o ka chromium ma kahi o 65%, aia ma waena o ke kālā (88%) a me ka nickel (55%).Ma muli o ka hoʻololi ʻole ʻana o ka chromium i ke kala, hiki iā ia ke mālama i kona reflectivity no ka manawa lōʻihi a ʻoi aku ka maikaʻi ma mua o ke kālā a me ka nickel.

6 KaʻAnuʻu: Chrome plated koʻokoʻo Polishing ma hope o plating

ʻO ka electroplating a me ka polishing: ʻelua mau ala like ʻole no ka mālama ʻana i nā metala a me nā mea ʻē aʻe.ʻO ka hana mua he lāʻau kemika, a ʻo ka hope he lāʻau mechanical.

Electroplating: ʻO ke kaʻina hana o ka hoʻohana ʻana i ka electrolysis e hoʻopili i kahi papa kiʻiʻoniʻoni metala ma ka ʻili o kahi metala a i ʻole nā mea ʻē aʻe.Hiki iā ia ke pale i ka corrosion, hoʻomaikaʻi i ka pale ʻana i ka lole, conductivity uila, reflectivity a hoʻonui i ka aesthetics.

Hoʻopololei: E hoʻohana i nā mea hana hoʻoliʻiliʻi maʻalahi a me nā ʻāpana abrasive a i ʻole nā mea hoʻoliʻiliʻi ʻē aʻe e hoʻololi i ka ʻili o ka mea hana.ʻAʻole hiki i ka polishing ke hoʻomaikaʻi i ka pololei o ka dimensional a i ʻole ka pololei geometric o ka mea hana, akā ke manaʻo nei e loaʻa ka ʻili maʻalahi a i ʻole ka aniani aniani.

7 ʻanuʻu: Chrome plated rod Quality Testing

ʻO nā koʻokoʻo piston i loaʻa i nā kaʻina electroplating a me ka polishing e hui pū ʻia me nā hemahema uhi e like me nā lua chrome a me ka pitting.Hoʻopili pololei ka nui a me ka nui o kēia mau hemahema i ka hana o ke koʻokoʻo piston.No ka ho'ēmiʻana i ka hopena o kēia mau hemahema ma luna o ke koʻokoʻo piston, ma kekahiʻaoʻao, ma ka hoʻomaikaʻiʻana i ka maikaʻi o nā mea maka, ka hoʻomaikaʻiʻana i kaʻenehana hana, a me ka ho'ēmiʻana i nā hemahema;ma ka ʻaoʻao ʻē aʻe, pono e ʻike pono i nā hemahema plating ma hope o ke kaʻina polishing e pale aku i nā huahana kūpono ʻole mai ka haʻalele ʻana i ka hale hana.Hoʻomaopopo nā ʻenekinia o Autoair i ka ʻike ʻana i nā hemahema me ke kōkua o ka ʻike ʻepekema kiʻi

8 KaʻAnuʻu: Hoʻopili

FAQ:

Q1: He aha ka pneumatic cylinder piston rod?

A: ʻO ke koʻokoʻo piston kahi mea koʻikoʻi a koʻikoʻi o kēlā me kēia hydraulic a pneumatic cylinder.ʻO ke koʻokoʻo piston ka lōʻihi o ka mīkini paʻa paʻa paʻa i hoʻopaʻa ʻia i ka pahu kila i hoʻopaʻa ʻia e hoʻouna i ka ikaika i hana ʻia e ka piston i ka mea mīkini e hana ana i ka hana.

Q2: He aha ke kumu o ka pneumatic cylinder piston rod?

A: ʻO ka piston pneumatic cylinder i loko o ka cylinder e lawe i ka ikaika a huki paha i hana ʻia e ka ea, a hana pololei ma ka pneumatic cylinder piston rod pili me ka piston, a laila pili ka pneumatic cylinder piston rod i ka mea hana ukana e neʻe ai. i hope a i waho.

Q3: He aha ka mea maka o kāu pneumatic cylinder piston rod

A: ʻO ka mea maʻamau, ʻo ka pneumatic cylinder piston rod o ka pneumatic cylinder e koho i ka 45 # kila e like me ka mea maka.Inā pono e hoʻohana ʻia ka cylinder i hana ʻia i kahi kaiapuni kūikawā, hiki ke hoʻohana ʻia ke kila stainless 304

Q4: No ke aha e koho ai i ka 45 # kila e like me ka mea maka

A:45 # kila he kila kila kila kiʻekiʻe me ka paʻakikī haʻahaʻa a me ka ʻoki maʻalahi.Ma hope o ke kinai ʻana, hiki i kona paʻakikī ʻili ke hiki i 45-52HRC.A hiki iā ia ke loaʻa i ka hana ʻoki maikaʻi a me ka ikaika kiʻekiʻe, ka paʻakikī a me nā waiwai mechanical piha, no laila ʻo ia kekahi o nā mea maʻamau i hoʻohana ʻia no nā ʻāpana shaft.

Q5: He aha ke kaʻina hana machining o kāu pneumatic cylinder piston rod?

A: I mea e loaʻa ai ka maikaʻi o ka mīkini paʻa, ʻaʻole ʻae ʻia ka hoʻopololei lima ʻana o ke koʻokoʻo piston ma hope o ka hoʻomaka ʻana o ka mīkini.No laila, pono e hoʻokō ʻia ke kaʻina hana pololei ma mua o ka mīkini.Ma muli o ka paʻakikī ʻole o ka mea hana, pono e hoʻokō ʻia ka huli ʻana a me ka huli ʻana i ka wā o ka mīkini hana e hoʻomaikaʻi i ka pololei o ka mīkini.ʻO ke ʻano hana o ke koʻokoʻo piston ʻo ia ka neʻe laina laina.I mea e hoʻomaikaʻi ai i ke ola lawelawe o ke koʻokoʻo piston, pono e uhi ʻia ka chrome e hoʻomaikaʻi i ka paʻakikī o ka ʻili a me ka pale ʻana.Ma hope o ka chrome plating, pono ka hana polishing no ka loaʻa ʻana o ka ʻeleʻele o ka ʻili kiʻekiʻe, hoʻemi i ka friction factor, a hoʻomaikaʻi i ka hana sila.No ka mea, ʻaʻohe hopena o ke kaʻina hana polishing i ke anawaena o waho o ke koʻokoʻo piston, pono e hoʻokō ka mea hana i kahi ʻoi aku o ka ʻili ma mua o ka uhi ʻana i ka chrome.No laila, pono e hoʻohui i kahi kaʻina wili maikaʻi ma mua o ke kaʻina hana chrome plating (hiki i ka wili pololei ke hoʻomaikaʻi i ka pili ʻana o ka chromium. ).Ma muli o ka nānā ʻana i luna, ʻo nā kaʻina hana kūpono no ke koʻokoʻo piston ʻo ia: hoʻopololei-holo ʻala-holo maikaʻi-wili maikaʻi-wili ʻana-chrome plating-polishing.

Q6: He aha ka polishing o pneumatic cylinder piston rod

A: I ka wā o ka hoʻohuli ʻana, ʻo ka lua waena e hoʻokani ana i kahi kūlana o ke kūlana e hōʻike i kahi pae o ka lole.I mea e hōʻoiaʻiʻo ai i ke kumu lokahi o nā benchmarks, pono e ʻoki ʻia ka lua waena ma mua o ka wili ʻana e hōʻoia i ka maikaʻi o ka hana.I ka wā e wili ai, pono e hoʻokō ʻia ka wili hoʻāʻo ma ka pōʻai waho kokoke i ka hopena mua, a hiki ke hana ʻia ka wili ʻana o ke koʻokoʻo piston i ka wā e hoʻokō ai ke kūlana runout i nā koi o ka hana.Ma waho aʻe o ka hoʻomaikaʻi ʻana i ka pololei dimensional, pono e loaʻa i ke kaʻina wili maikaʻi ke kiʻekiʻe o ka ʻili o ka ʻili ma ka ʻili mīkini e hoʻomaikaʻi ai i ka pili o nā ion chromium i ka wā o ke kaʻina electroplating.I mea e hōʻoia i ka mānoanoa o ka chromium plating layer o ka hope piston koʻokoʻo like like, ka roughness ili ma hope o ka wili maikai e pono e kokoke i ka roughness ili ma hope o chromium plating a polishing.Inā makemake ʻia ka ʻili o ka ʻili o ke koʻokoʻo piston e kiʻekiʻe, e like me Ra <0.2 μm, pono ia e lepo maikaʻi.Hoʻohui i ka wili maikaʻi loa a i ʻole ka hana polishing ma hope o ka wili ʻana.

Lawe i ke kuleana piha e hoʻokō i nā koi āpau o kā mākou mea kūʻai;e hoʻokō mau i ka holomua ma ka paipai ʻana i ka ulu ʻana o kā mākou mea kūʻai;e lilo i hoa hana paʻa hope loa o nā mea kūʻai aku a hoʻonui i ka makemake o nā mea kūʻai aku no ka Chinese Professional China S45c SAE1045 C45 Hot Rolled Carbon Steel Sheet, Ke manaʻoʻiʻo nei mākou i ka maikaʻi ma mua o ka nui.Ma mua o ka hoʻokuʻu ʻia ʻana o ka lauoho, aia ka mākaʻikaʻi koʻikoʻi kiʻekiʻe i ka wā o ka mālama ʻana e like me nā kūlana maikaʻi o ka honua.

ʻOihana PākēPepa kila Kina, Pepa kila i olokaa wela, Uaʻike pono kā mākou hui i nā koi o ka mākeke ma nā'āina likeʻole, a hiki iā ia ke hoʻolako i nā huahana kūpono kūpono a me nā hoʻonā i nā kumukūʻai maikaʻi loa i nā mākeke likeʻole.Ua hoʻonohonoho mua kā mākou hui i kahi hui ʻike, noʻonoʻo a kuleana e hoʻomohala i nā mea kūʻai aku me ka manaʻo multi-win.